YOU MAY ALSO BE INTERESTED IN…

Tractor Implement Automation Precision Ag Technology

- Simplified operation: e.g. one touch, one bale

- Maximise throughput and higher productivity

- Relaxed working and reduced stress for the operator

- Consistent bale quality, planting and other work results

- Reduced fuel consumption

Related Products

AutoTrac Universal 300

AutoTrac Controller

AutoTrac

AutoTrac Turn Automation

AutoTrac Vision

AutoTrac Implement Guidance - Passive

Active Implement Guidance

Tractor Integrated Active Implement Guidance

Machine Sync

In-Field Data Sharing

Active Fill Control

AutoTrac RowSense

Perfect results every time

Collapse All

Expand All

Perfect results every time

Tractor Implement Automation manages automatic adjustments of electronically controlled tractor functions. This award winning concept not only enables maximum productivity and consistent work results at all times but also reduces operator fatigue and stress. No matter whether you are pressing bales, planting or harvesting potatoes, planting corn or applying manure – there is an impressive solution for it all.

Compatible with:

- John Deere Round Balers

- John Deere Manure Sensing

- Horsch Maestro

- Grimme Exacta & Root Runner

- Krone Fortima, Comprima and Ultima balers

- Fliegl Manure Sensing

John Deere 400R fixed chamber balers and 900 Series round balers no longer need a separate implement-specific baler automation activation. John Deere F441R, V451R and V461R round balers feature this capability in the base configuration. 900 Series balers can easily be upgraded by your dealer back to model year 2012. All that is required to make it a plug and play solution is the Tractor Implement Automation Activation, which comes in the base configuration with GreenStar and AutoTrac Ready 6R tractors since model year 2016.

Features

Collapse All

Expand All

Automated adjustment of all ISOBUS connected functions

Tractor Implement Automation (TIA) enables automated adjustments of electronically-controlled tractor functions. The implement communicates with the tractor via the ISOBUS. The following functions can be automated by TIA:

- Steering

- Auxiliary valves (state, flow)

- Rear power take-off (PTO) (engagement and gear)

- Front PTO (engagement)

- Rear hitch

- Vehicle speed (IVT™/AutoPowr™ transmission, CommandQuad™ transmission, PowerShift™ transmission)

- Drive strategy

Currently implements supporting TIA are available from John Deere, Grimme®, Krone®, and Horsch® companies.

John Deere Tractor Baler Automation (TBA)

The automation makes baling easy and accurate. Recurring actions are triggered automatically. The tractor is stopped when the bale size is reached and the tying is triggered. The gate is opened, the bale ejected, and as the bale is unloaded, the gate is closed again. The only operator action remaining is to forward the reverser. The tractor is put to stop if a plug occurs, which avoids damages to the PTO and increases the unplugging efficiency. In summary, growers benefit from the following advantages:

- High baling comfort (one manual action versus four) – operators can better focus on machine optimization versus having to constantly execute repetitive actions

- Error-proof baling – even after 10 working hours, the system does not forget an action; a true advantage especially for inexperienced operators.

- Constant bale quality – same diameter bale after bale.

- Maximum productivity at all times – no reduced efficiency due to operator’s fatigue

John Deere Machine Sync

John Deere Machine Sync utilizes the John Deere Machine Communication Radio (MCR) to communicate digital data between the machines relative to position, speed, direction of travel, and in the case of combines, grain tank status. Once pairing occurs between a combine and a tractor, Machine Sync controls the tractor's speed and steering (AutoTrac™ assisted steering system), mimicking the movements of the combine and facilitating the efficient on-the-go unloading of the combine. Additionally, Machine Sync provides all machines within a single network real-time logistics visibility for every machine as well as grain tank fill status for all combines within the network.

John Deere Manure Sensing

Manure Sensing

Manure Sensing

John Deere Manure Sensing enables real-time constituents measurements in liquid organic fertilizers using the field-proven HarvestLab™ sensor which, in this case, can be installed and flexibly moved between various application systems including umbilical/drag line systems and across several slurry tanker brands. The near infrared (NIR) sensor is able to measure the key constituents of liquid manure ingredients such as total nitrogen, ammonium-nitrogen, phosphorus, potassium, and dry matter with more than 4000 measurements points per second during application in the field. With John Deere Manure Sensing, slurry application can now be based on a nutrient target rate (kg/ha) for one ingredient with an optional limit rate for a second ingredient, and if desired, also based on a prescription map. It enables very precise application of organic nutrients with an agronomical optimized site-specific fertilization rate in kg/ha instead relying on an estimated average nutrient level by applying a certain amount of m³/ha.

John Deere 6x30P, 6R, 7R, and 8R Tractors with AutoPowr (IVT) or e23™ transmission equipped with Tractor Implement Automation (TIA) can achieve the desired application rate faster and more precisely than any rate control system (with flow based regulation only) in a fully automated and comfortable manner. If due to hilly conditions and heavy engine load, for example, the tractor cannot reach the required speed, the fully integrated systems with partnering slurry tanker manufacturers like Fliegl Agrartechnik, Samson Agro, and Joskin can additionally allow the flow adjustment accordingly.

Grimme root runner

The automation is executed through a mechanical feeler on the front implement. The sugar beet row is identified through this sensor, and a steering signal is sent to the tractor to keep it on track. A precise steering system is needed to keep the tractor wheels from running over the row of sugar beets and pushing them further into the ground, complicating the digging process. The steering automation supports the driver in an extraordinary way, especially during long working hours and at night.

Grimme GL 420 Exacta

Potato planter

Potato planter

A sensor on the potato planter combined with TIA enables a Grimme controller to adjust the tractor’s hitch height in order to maintain a constant planting depth.

This constant planting depth ensures uniform and optimized growing conditions while reducing wear and fuel consumption by keeping the tillage implement at just about the right depth.

Krone Fortima, Comprima, and Ultima

The automation enables automated speed control, meaning as soon as the bale chamber has reached the optimal filling or the operator starts the tying process manually, the tractor will come to a stop (Fortima and Comprima). With the Ultima, continuous work is possible due to speeding up and down for tying and bale ejection. Both Comprima and Ultima use onboard hydraulics to open the tailgate while the Fortima does it automated through the tractor’s selective control valve (SCV).

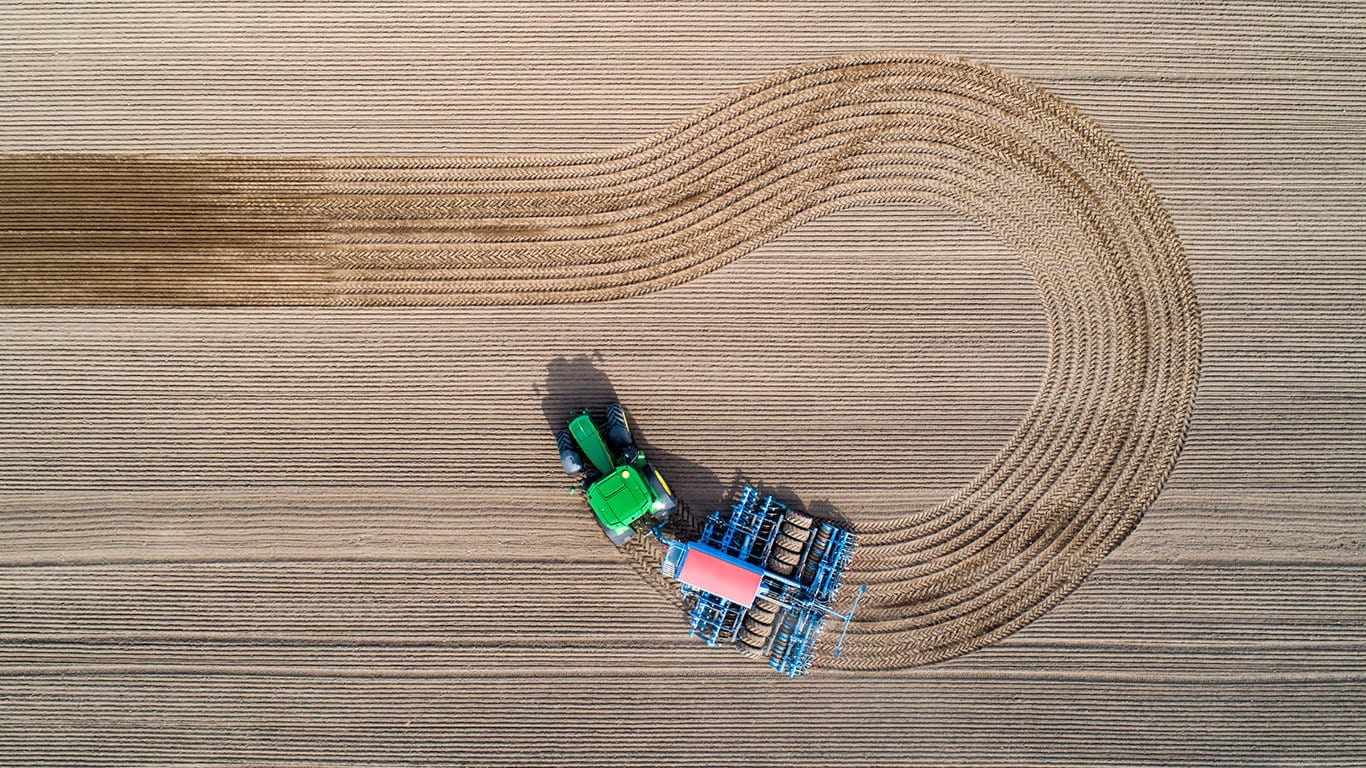

Horsch Maestro

Horsch Maestro

Horsch Maestro

TIA will also be compatible with Horsch Maestro planters equipped with the Horsch E-Manager Terminal (red cover). Based on implement feedback, the working speed will be automatically regulated in order to keep seed placement accuracy and coefficient of variation at the desired level while maxing out the working speed. While using the AutoSpeed functionality, the operator can adjust the precision of the seed placement. The Maestro will command the speed adjustment to the John Deere Tractor based on the deviation from the target speed. In this way, the variation coefficient are kept as constant as possible.

Grimme is a trademark of Grimme Landmaschinenfabrik, GmbH & Co. KG. Krone is a trademark of Bernard Krone Holding GmbH and Company. Horsch is a trademark of Horsch Maschinen GmbH.

Tractor Implement Automation (TIA) offers a new baling experience

The optional TIA makes baling even easier. This exclusive system manages most of the baling process and gives the grower the following advantages:

- High baling comfort - a single action to bale instead of four.

- Error-proof baling - even after 10 working hours, the system does not forget any action; a true advantage for an inexperienced driver.

- Constant bale quality - same diameter bale after bale.

- Constant productivity - no reduced efficiency due to operator’s fatigue.

When used with a John Deere ISOBUS tractor, electric selective control valve (E-SCV), and AutoPowr™ transmission, the system will be able to:

- Stop the tractor when bale size is reached

- Open the gate

- Close the gate when bale is unloaded

The only action remaining is to forward reverser and manage the steering.

There are two levels of Tractor-Baler Automation:

- Level 1: selective control valve (SCV)

- Net/twine

- Requires electronic SCVs

- Available for any tractor transmission

- Operator must stop tractor

- Gate automatically opens and closes

- Tractor speed must be at zero before gate will open

- Net/twine

- Level 2: SCV and machine-speed control

- Net/twine

- Requires electronic SCVs

- Requires an IVT™/AutoPowr tractor

- Operator does not have to stop tractor; tractor is slowed and comes to a stop on its own

- Net/twine

The gate automatically opens and closes. To resume forward motion, the operator has to either take the reverser out of forward, into neutral position, and back to forward position or press and hold the brakes before it comes to a complete stop and let off brakes to move forward.

The Tractor-Baler Automation solution is available for:

John Deere tractors:

- ISOBUS ready

- 6030 Premium Series model year 2010 and newer

- 6R Series model year 2011 and newer (iTEC™ system ready)

- 7030 Premium Series model year 2010 and newer

- 7R Series model year 2011 and newer

NOTE: New 6R Final Tier 4 (FT4) models do not require iTEC since May 2015 ISOBUS option includes TIA.

John Deere balers:

- 469 Premium

- 569 Premium

- 960 (offer ISOBUS compatibility as base equipment)

- 990 (offer ISOBUS compatibility as base equipment)

- V451R (in base)

- V461R (in base)

NOTE: Premium round balers can run on any tractor that is ISOBUS compatible (or made ISOBUS compatible with wiring harness).

User-friendly interface

Main page with simple and clear pictograms

Main page with simple and clear pictograms

Bale or soft-core density adjustments

Bale or soft-core density adjustments

The baler interface displays information that is needed. The R-Series and the 900 Series Variable Chamber Round Baler monitors provide all required information:

- Bale shape and diameter

- Drop floor and knives position

- Soft core activation

- Tying process status

- Gate position

- Maintenance status

Adjustments can also be managed from the operator’s station:

- Bale size and density

- Soft-core diameter and density

- Net and twine tying parameters

- Knives selection

- Automated lubrication

- Tractor Implement Automation status

- Bale counter resets