YOU MAY ALSO BE INTERESTED IN…

Machine Sync Precision Ag Technology

- Wirelessly connects multiple machines - tractors, combines, and SPFH in their own network. One machine acts as the ‘Leader’, controlling the speed, direction and position of the ‘Followers’.

- Ensures spill-free, precision unloading on-the-go

- Prioritises combine unloading and improves harvest efficiency

- Reduces the chance of collisions between machines

Combine to Tractor

Gen4 Machine Sync allows harvest operators to connect up to 6 machines with their own wireless network. The combine acts as the Leader, synchronising the speed of the tractor and its direction for precision unloading on-the-go.

The combine driver can nudge the tractor back and forth to ensure even loading of the grain cart. Individual combines in the same workgroup can also share their Grain Tank Fill-level and Unloading Auger Status with the tractors for better harvest logistics and coordinated unloading.

Related Products

AutoTrac Universal 300

AutoTrac Controller

AutoTrac

AutoTrac Turn Automation

AutoTrac Vision

AutoTrac Implement Guidance - Passive

Active Implement Guidance

Tractor Integrated Active Implement Guidance

In-Field Data Sharing

Tractor Implement Automation

Active Fill Control

AutoTrac RowSense

Tractor to Tractor

Machine Sync is a great solution when using pull-type harvesting machines for speciality crops such as potatoes or onions. The lead tractor is able to coordinate the movements of the unloading tractor for safe unloading. It’s particularly important in operations where the unloading wagon has to be in close proximity to the harvester. Machine Sync ensures a constant distance between machines throughout the unloading sequence and avoids potential damaging collisions.

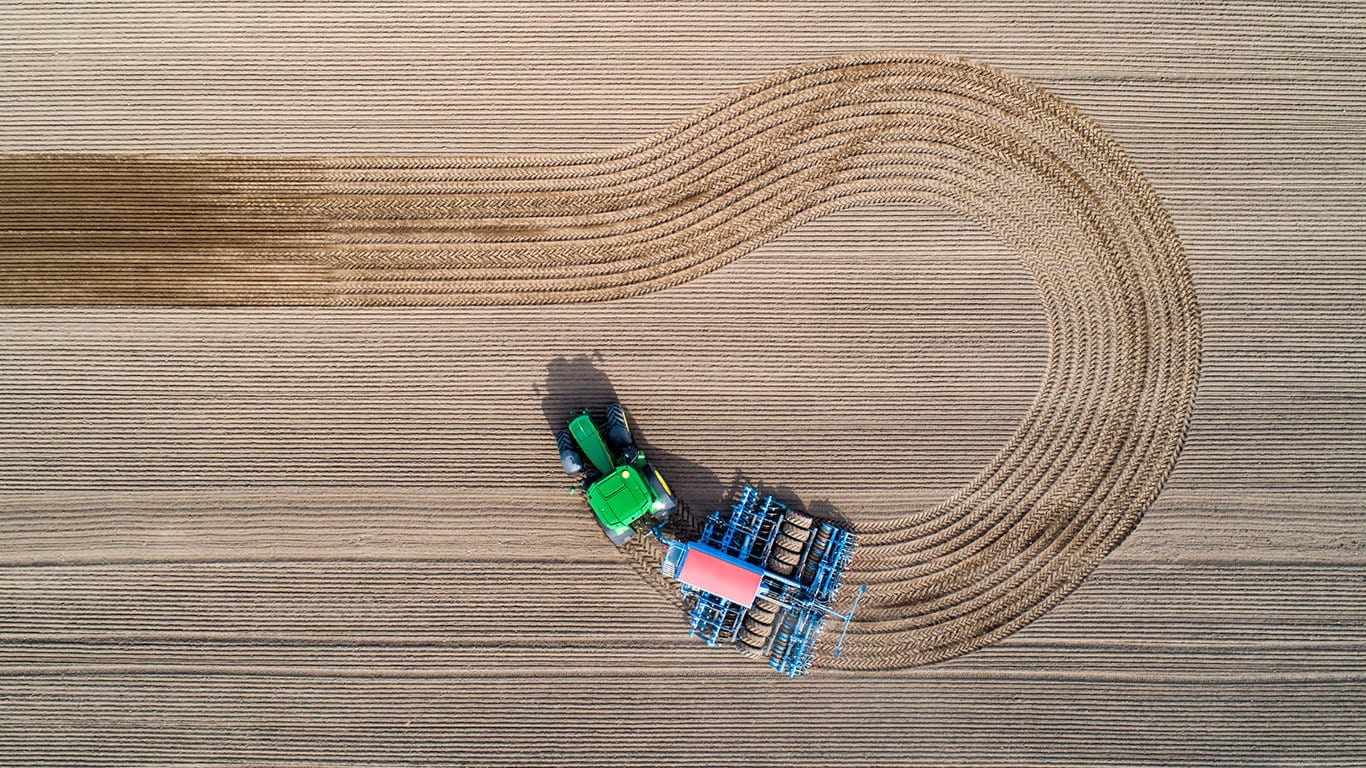

SPFH to Tractor

Machine Sync sets up a ‘U’ shaped zone around the SPFH which is particularly useful for direct load harvesting operations where a tractor and silage wagon need to be within close proximity of the harvester at all times. The SPFH can control the speed of tractors from the right, rear or left for spill free unloading. The ability to control two tractors simultaneously also facilitates better handover from one silage wagon to the next and reduces crop spillage