VIEW PRODUCT BROCHURE

Gator Utility Vehicles Brochure

2030A Work Utility Vehicles

- 7-gauge, formed-steel frame

- Wide, low cargo bed

- A pro on golf courses and sports fields

- 5 speed synchromesh transmission

Experience the attitude

Meet our club professional! From spraying and top dressing to debris collection, the ProGator utility vehicle helps you keep your turf in peak condition. Even with the maximum payload of 1535 kg, the power steering and tight turning radius make it a pleasure to drive.

Looking for more choices?HD200 Sprayer

TC125

* incl. 90 kg driver, 90 kg passenger & accessories

Features

Collapse All

Expand All

Strong, 7-gauge steel frame

ProGator™ A Series frame

ProGator™ A Series frame

- Welded 7-gauge, 0.177-in. (4.5-mm) steel for optimum strength, durability, and performance

- Laser cut and formed steel construction for enhanced durability

- Rubber-mount isolated engine, transaxle, and exhaust system for smooth, quiet operation

- Electrostatic primary paint with secondary powder paint for extra corrosion protection from the elements

- Standard front bumper integrated into the frame

Large-capacity fuel system

ProGator™ A Series fuel system

ProGator™ A Series fuel system

The ProGator fuel system provides the following benefits:

- 8 U.S. gal. (30.3-L) capacity allows a full day of run time without the need for refueling.

- Large filler-neck opening, 3.5-in. (89 mm), makes it easier to fill and has a reduced chance of foam overflow with diesel fuel.

- Fuel gauge is dash mounted.

Easy-to-use cargo box with optional bedliner for tough hauling tasks

The ProGator™ heavy-duty utility vehicles feature an optional cargo box for hauling items on the golf course. The cargo box attaches to the ProGator easily, utilizing only two rear pivot pins and one lift cylinder pin. This allows quick and easy changes between ProGator attachments.

A 16-gauge steel frame provides added strength and durability. A standard hydraulic lift and lower cylinder allow for easy lifting of the cargo box to dump sand and other items from the cargo box quickly and easily.

The optional tailgate release kit allows for a dump truck mode, where the tailgate automatically opens from the bottom when the tailgate is raised to allow items to flow out of the box. The tailgate then automatically closes when the box is lowered for fast and efficient operation.

Cargo box pin system and striker plate

Cargo box pin system and striker plate

Cargo box in locked position

Cargo box in locked position

For normal tailgate operation, opening and closing the tailgate is easier than ever. An innovative retractable pin system is the key. A spring-loaded L-pin is located on each end of the cargo box.

To open the cargo box, simply pull the L-pins inward and lower the tailgate. Closing the tailgate is even easier. The angled striker plate design allows the L-pins to automatically retract when shutting the tailgate. When the cargo box is fully closed, the springs will pull the pins into their locking position. This allows for a one-handed closing of the tailgate, similar to that of a pick-up truck.

A bedliner can be ordered as an optional attachment for the ProGator machines. The high-density polyethylene bedliner is stamped with the John Deere logo and protects the steel cargo box and paint from dirt and debris.

The bedliner is designed to wrap around the bottom of the tailgate, preventing gravel and other debris from getting trapped under the bedliner. The bedliner ribs are tapered, allowing materials to flow freely out of the cargo box when it is lifted or being cleaned.

ProGator A Series bedliner

ProGator A Series bedliner

Operating comforts and conveniences

ProGator A Series operator station

ProGator A Series operator station

Many of the standard features on a ProGator™ offer the operator and passenger a smooth, comfortable ride:

-

Side-by-side seating provides plenty of room for the operator and one passenger

- Standard hip restraints for rough terrain

- Position-adjustable high-back cushioned seats for additional comfort and support

- Hydrostatic power steering for ease of use and extra operator productivity

- Excellent visibility in operator platform and exceptional legroom for comfortable operation

- Ergonomically position controls on center console: five-speed gear shift, park brake, cargo box lift lever, optional hydraulic power take-off (PTO) engagement lever, differential lock, and optional 4WD engagement lever

- Automotive-style traction controls with a clutch on the left side, brake in the center, and throttle pedal to the right

- Cup holders at the rear of the console

- Dash-mounted gauges with nighttime illumination for early morning or evening operation: speedometer, fuel, tachometer, hour meter, and coolant temperature

- Dash-mounted indicator lights: oil pressure, battery voltage, glow plug (diesel only), coolant temperature, optional 4WD indicator light, and park brake

- Optional dash-mounted controls for sprayer applications

- Integrated glove box on passenger side of machine for convenient storage

Manual-engage four-wheel drive—when it's wanted

Four-wheel drive on ProGator™ A Series

Four-wheel drive on ProGator™ A Series

Manual-engaging four-wheel drive is a factory-installed option on both the 2030A ProGator Heavy-Duty Utility Vehicles. Manual engagement gives the operator ultimate control of when to use four-wheel drive in a given condition. Simply push the lever down to engage four-wheel drive, and pull up on the lever to return to two-wheel drive.

The 4WD system maximizes maneuverability and traction. By engaging only when the operator needs it, the manual 4WD system provides better fuel economy than a full-time 4WD system. The 4WD system can be used in any of the five forward gears and also works in reverse.

CAUTION: This vehicle should not be considered as an all-terrain vehicle (ATV).

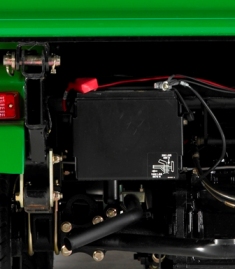

Fully regulated electrical system

ProGator™ A Series electrical system

ProGator™ A Series electrical system

The fully regulated electrical system provides the following:

- Heavy-duty 55-amp alternator for the necessary output to power all John Deere approved accessories

- Battery with 500 cold-cranking amps for quick, easy starting, even in cold weather

- Easy battery access at the rear of the machine for enhanced serviceability

- Easy access to fuses underneath the instrument panel

- Standard 37.5-W halogen headlights for excellent night or early morning visibility

- Standard rear taillights

- Standard dash-mounted horn

- Electronic speedometer that can be read in mile per hour kilometer per hour

- Digital hourmeter

Powerful Yanmar® gas and diesel engines

Yanmar diesel engine

Yanmar diesel engine

Rain cap

Rain cap

The ProGator 2030A is powered by a three-cylinder 22.1 hp (16.5 kW) Yanmar diesel engine featuring 1115 cc displacement, liquid cooling system, overhead valves and full-pressure lubrication.

Common features for both engines include:

-

Overhead valve design for greater efficiency and fuel economy

-

Rubber-isolated mounting that reduces vibration at the operator station for added comfort

-

Full-pressure lubrication system for positive lubrication, even when operating on slopes

-

Canister type replaceable air filter designed to eject 90 percent of debris before it reaches the paper element

-

Completely sealed for effective cleaning.

-

A secondary air filter element provides extra protection and filtering.

-

-

Standard rain cap located near the center of bed-mounted attachments limits the amount of debris and /or water exposure

-

Low fuel consumption and large, 8 U.S. gal. fuel tank

The following features can also be found on the 2030A Diesel model only:

-

Automotatic glow plugs when the key is switched to the run position for aid in winter starting

- Direct fuel injection for more efficient combustion and easier starting

- Standard air-restriction indicator

Yanmar is a U.S.-registered trademark of Yanmar Company Limited.

Dual hydraulic pump configuration

Auxiliary hydraulic pump

Auxiliary hydraulic pump

The 2030A ProGator™ Heavy-Duty Utility Vehicles feature two independent hydraulic pumps as standard equipment.

An 8.2-cc auxiliary hydraulic pump provides up to 7.64 gpm (28.9 l/min) of hydraulic flow on gas models and up to 7.47 gpm (28.3 l/min) on diesel models for powering hydraulically driven implements, such as the HD200 and HD300 SelectSpray, TC125 Turf Collection System, TD100 Topdresser, and more. This pump also lifts and lowers the cargo box with the use of a single lever located at the operator control station. This pump is driven off of the engine crankshaft.

A 5-cc steering pump provides up to 3.8 gpm (14.4 l/min) of hydraulic flow on gas models and up to 3.7 gpm (14.1 l/min) of hydraulic flow on diesel models for smooth and efficient power steering. This pump is driven off of the engine gear train.

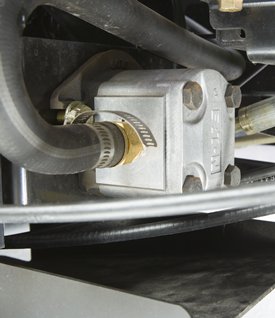

Hydraulically actuated front and rear drum brakes

A Series ProGator™ brakes

A Series ProGator™ brakes

Hydraulically actuated self-adjusting front and rear drum brakes provide ample stopping capacity when the vehicle is loaded at or below rated capacities.

The hand-controlled parking brake is designed to hold the vehicle in place on hills, in both the uphill and downhill directions.

To top off braking fluid, simply remove the front grille cover to easily access the brake fluid reservoir. No tools are needed to remove the front grille cover.

A Series ProGator brake lines

A Series ProGator brake lines

The braking system utilizes flexible brake lines to allow easy and efficient routing of the brake lines when performing any service or routine maintenance.

Large, turf-friendly wheels and tires

Standard rear wheel and tire

Standard rear wheel and tire

Front wheel and tire

Front wheel and tire

These are the largest standard-sized tires in the market for optimum ground clearance, traction performance, and weight distribution:

- Front 23x10.50-12 steering tires

- Rear 26x12.00-12 drive tires

- Optional 26x14.00-12 rear drive tires for a wider footprint and increased load carrying capacity when using sprayers and topdressers

- 4-ply ratings that improve wear characteristics and provide extra protection against flat tires

- Versatile turf tread design for good traction without damaging the turf

Additional tire and wheel options for turf applications

Additional tire and wheel options for turf applications

Additional tire and wheel options for turf applications

- Smooth front 22x9.50-12 front steering tires offer reduced turf damage. Traction in some conditions will be limited.

- Smooth rear 26x14.00-12 rear drive tires for a wider footprint where the least amount of turf damage is required, which is helpful for sprayer applications on the greens. Traction in some conditions will be limited.

- Fairway rear 26x14.00-12 drive tires offer a wide footprint with minimal turf damage when sprayers or topdressers are used.

- 4-ply ratings offer increased load carrying capacity with improved wear characteristics and provide extra protection against flat tires.

- Required tire option can be declared during machine configuration.

Smooth ride with power steering and leaf spring suspension

A Series ProGator hydrostatic power steering

A Series ProGator hydrostatic power steering

Hydrostatic power steering is standard on ProGator™ Heavy-Duty Utility Vehicles. The steering system has its own dedicated 3.4-gpm hydraulic pump driven by the engine gear train to ensure steering performance is maintained while other hydraulically driven implements are being used.

- Tight turning clearance circle (16.3 ft for two-wheel drive and 20.6-ft for four-wheel drive) for excellent maneuverability

- Smooth, responsive operation

-

Completely sealed for long life

A Series ProGator beam-type suspension

A Series ProGator beam-type suspension

Beam-type suspension with dual leaf springs and shocks on the front and rear provides:

- Fully independent operation for all four wheels, providing enhanced performance in rough terrain

- Superior strength and rigidity to keep rear implements from bottoming out on frame stops at low loads, providing a smooth ride at or below the payload capacity

- Simple design that features a small parts count compared to A-arm style suspensions used on some competitive utility vehicles

Over 2 tons of total payload capacity

Need the payload to handle tough jobs on the golf course? The ProGator™ delivers with over 2 tons* of payload capacity. No need for a dedicated vehicle for that 300 gallon sprayer. No need for a vehicle that just hauls and does nothing else. The ProGator delivers the best of both worlds by providing a high payload capacity in a versatile package where sprayers, a cargo box, and other attachments can be interchanged in minutes without tools.

Actual payload capacities are as follows:

| ProGator 2030A | |

| Capacities (model year 2011 machines only) | |

| Payload capacity (including 200 lb operator, 200 lb passenger, and loaded attachment), lb (kg) | |

| 2WD with standard suspension | 3414 lb (1549 kg) |

| 4WD with standard suspension | 3287 lb (1491 kg) |

| 2WD with heavy-duty suspension, wide rear tire, and 4-Post ROPS | 4157 lb (1886 kg) |

| 4WD with heavy-duty suspension, wide rear tire, and 4-Post ROPS | 4030 lb (1828 kg) |

* When equipped with heavy duty front and rear suspension kit, wide rear tire kit, and 4-Post ROPS conversion kit.

Five-speed synchromesh transmission with differential lock

Transaxle

Rear transaxle

Rear transaxle

Fourth/fifth-gear lockout

Fourth/fifth-gear lockout

-

Five-speed synchromesh design enables easy shifting on the go without needing to stop to select a range. The synchromesh system allows the operator to start driving in any gear. It is not necessary to start in first gear and shift through the remaining gears.

- Standard fourth-gear and/or fifth-gear lockout limits the top ground speed when desired. They are located on the transaxle at the rear of machine to prevent operators from changing this setting from the operator station.

- Transaxle is fully enclosed and runs in hydraulic oil for optimum lubrication and enhanced reliability.

- Helical gears are used for quiet operation.

- Automotive-style single-plate clutch enables easy operation.

- There are five forward, neutral, and reverse gear selections.

- There is a neutral-start safety interlock.

Differential lock

Differential lock

Differential lock

- Provides increased traction by locking both rear drive wheels together

- Built into the transaxle as standard equipment

- Conveniently located orange-capped handle on the operator console to make it easy for the operator to engage the differential lock while driving

- Manually engaged to allow the operator to have control over when this feature is engaged

- Reduces scuffing on the turf while turning because the inside wheels turn slower than the outside wheels (vehicles that have a solid axle shaft must skid the inside wheel when making a turn)

Standard ROPS with seat belts

ProGator™ A Series ROPS

ProGator™ A Series ROPS

A two-post rollover protective structure (ROPS) and retractable seat belts are standard equipment on the 2030A ProGator Heavy-Duty Utility Vehicles. The two-post ROPS meets the Occupational Safety and Health Administration's Part 1928 standard.

The seat belts must be worn at all times during operation by both operator and passenger.

Zero grease points and convenient servicing locations

ProGator™ A Series

ProGator™ A Series

Diesel engine in ProGator A Series

Diesel engine in ProGator A Series

Sealed bearings throughout make the ProGator A Series Heavy-Duty Utility Vehicles a dream to service. The 2WD models have zero lubrication points, while the 4WD models have two lubrication points on the U-joints of the 4WD shaft and one lubrication point on the slip joint. Sealed bearings do not require grease or periodic maintenance.

No tools are required to access the brake fluid fill, either. Simply remove the front grille to access the fluid fill.

All other daily service points are accessed by simply lifting the cargo box and engaging the lift cylinder safety support. Such service points include the coolant level, engine oil level, air-restriction indicator, and more.