New PowrSpray for high specification sprayers

Precision Spraying at the push of a button

John Deere’s new PowrSpray solution system for high specification R900i Series trailed sprayers, which are now available in three tank sizes of 4400, 5200 and 6200 litres, is the company’s latest innovative development in crop care technology.

PowrSpray features two hydraulically-driven centrifugal pumps. The first fills the sprayer at up to 1200 litres/min, while the second, a 1000 litre/min spraying pump, has Direct Rate Control for fast changes of application rate and the highest spraying accuracy.

The self-priming, low pressure filling pump fills the sprayer rapidly even with the tractor engine at idle, thus reducing fuel use and noise during the filling process.

In addition, Direct Rate Control of the spraying pump is able to adjust between minimum and maximum output in less than three seconds, increasing rate control accuracy to a level that conventional systems cannot match. This is especially important during headland entry and exit, where changing forward speeds and automatic section switching place heavy demands on rate control systems.

Direct Rate Control also significantly improves the accuracy achieved in variable rate applications, where large changes in target rate may be required.

Combined with ‘smart’ hydraulic control of the solution system, Direct Rate Control allows spraying to be completed independent of the tractor engine rpm. AutoPowr IVT or DirectDrive tractors with engine/transmission management can be operated in 'ECO' mode, with the low engine rpm significantly reducing fuel consumption during spray applications.

PowrSpray comes as standard with Auto Filling, Auto Agitation Intensity control (where the tank agitation intensity decreases as the solution tank level lowers), Power Agitation (for maximum intensity agitation of difficult to mix products) and the unique Auto Dilute rinsing system. R900i Series PowrSpray machines can also be optionally equipped with John Deere's automatic Section Control and BoomTrac auto boom levelling systems.

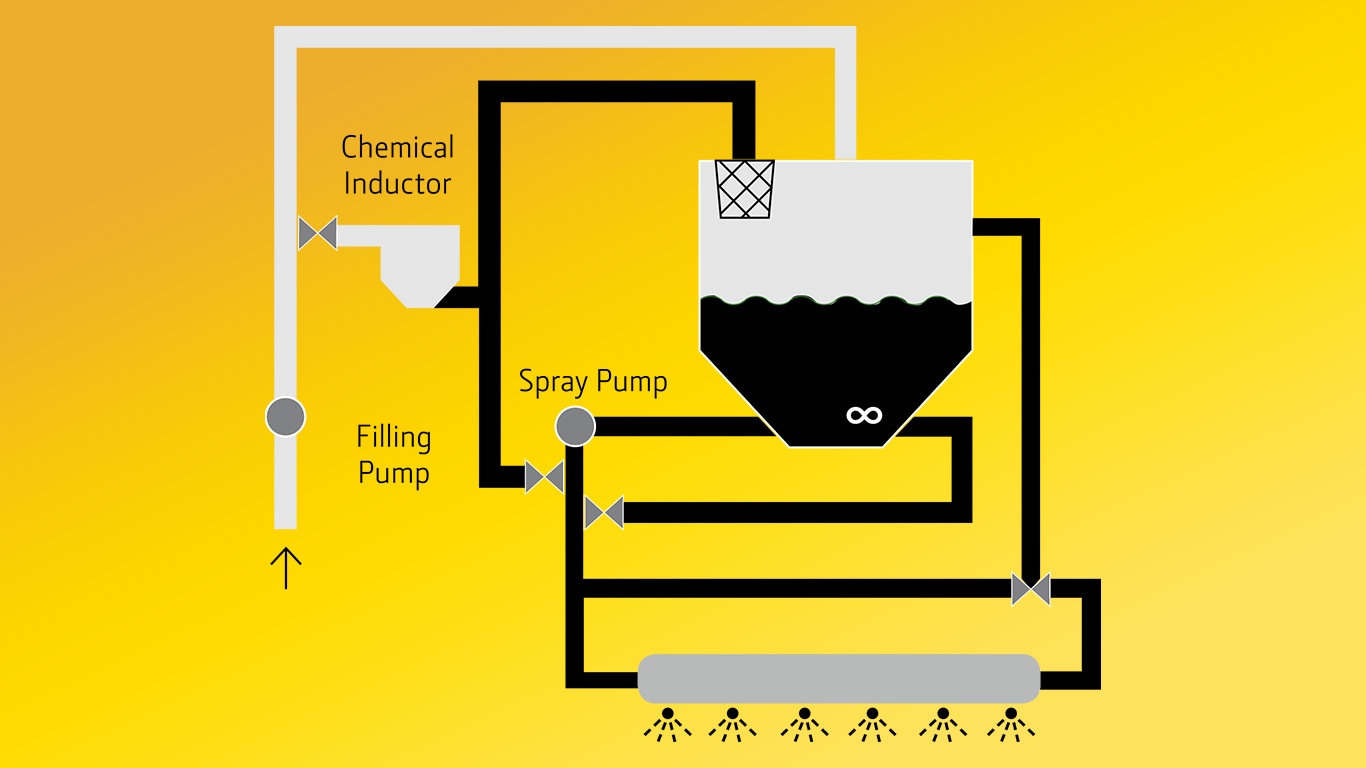

UNIQUE MAINTENANCE-FREE DUAL CIRCUIT SYSTEM

PowrSpray features 2 liquid circuits: A Spraying Circuit, powered by a 750l/min high pressure spraying pump and a completely separate Filling Circuit, with a 1200l/min pump optimized for rapid tank filling. The filling circuit is never in contact with the spray liquid, so residual volume is reduced by 45% compared to conventional systems and rinsing is faster and more effective.

Both pumps operate independently of the tractor engine RPM, so you even can spray with your engine at idle - reducing noise and fuel consumption. The Unique Dry-run Protection automatically shuts down the pumps if no liquid is present, protecting the pumps from incorrect operation.

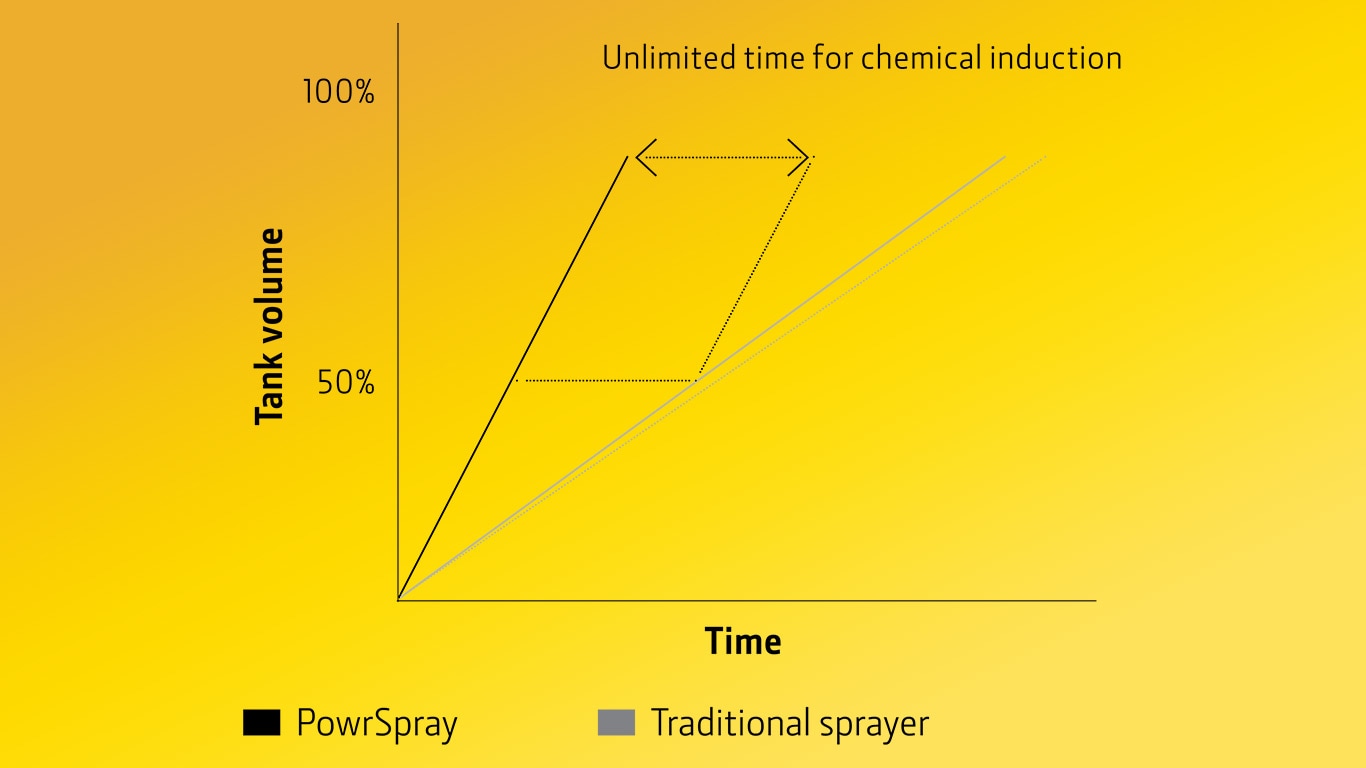

FAST AND RELAXED FILLING

Need to fill quickly for a fast turnaround? The Filling pump delivers liquid at up to 1200l/min into the solution tank. When adding chemicals, the practical Active Pause feature providesall the time you need to measure and fill chemicals, while still providing clean water for rinsing jugs or used containers.

The traditional „race“ against the filling solution tank is no more. Filling with PowrSpray is simple and completely relaxed.

POWERFUL AND ADJUSTABLE AGITATION

Agitation with PowrSpray is more powerful, yet more precise, than on conventional machines. Pumps are driven independently of the tractor engine RPM, so you can agitate the tank contents even when transporting at full speed.

Agitation intensity can be set from the cab and automatically reduces as you spray the tank empty, to prevent foaming. There is even a new Power Agitation mode, providing an extreme stirring action to recombine sedimented products after standing for long periods- for example after interruptions caused by the weather.

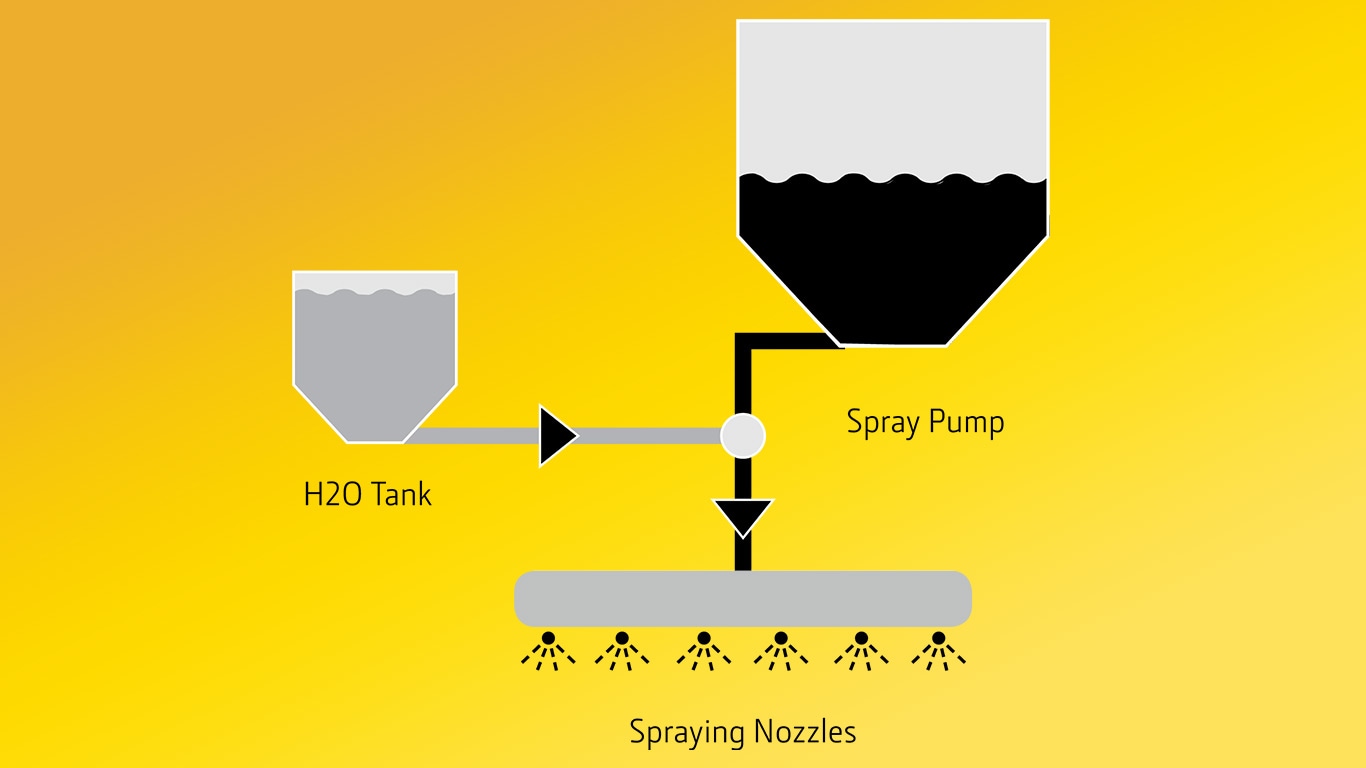

PERFECT CONTROL FOR PRECISE SPRAYING

For precision spraying, the speed of Application Rate adjustment is crucial. To guarantee consistently accurate performance, PowrSpray features Direct Control of the spraying pump for extremely fast rate adjustment. It perfectly compliments the wide booms, automatic Section Control and site-specific spraying abilities of John Deere sprayers.Overdosed and underdosed areas are minimised or completely eliminated - even during Variable Rate spraying tasks with widely different application rates. The Spraying Pump also operates independently of the tractor engine RPM, allowing you to reduce engine speed, resulting in lower noise and fuel consumption levels.

LOWEST RUNNING COSTS-ZERO REGULAR MAINTENANCE

PowrSpray has been designed from scratch to be highly efficient and offer the lowest possible long-term running costs. Unnecessary moving parts have been eliminated and proven components used wherever possible, ensuring maximum uptime.

Innovative Run-Dry protection prevents accidental damage and the PowrSpray wet system needs no regular maintenance, keeping ownership costs at rock bottom.

A CLEAN SOLUTION

The powerful but simple Dual Circuit design of PowrSpray features 45% lower residual volume than previous machines. Less liquid is left in the machine after spraying and rinsing out can be completed quickly and with greater efficiency. At a touch of an in-cab button, the rinsing and dilution system is enabled, automatically following the required rinsing mode. Nothing is left to chance, with the whole solution system thoroughly cleaned. Even when changing crops or chemicals, you can be sure your machine is thoroughly clean.