Electronic Solutions

Telematics

Advanced, yet rugged communication products and services that give you efficient logistics, reduced maintenance, and cost control.

Reporting, monitoring, and controlling machine operations through telematics promises to revolutionize heavy machinery-based industries.

The benefits are efficient logistics, reduced maintenance, and cost control. Our systems integrate advanced communication technologies, such as CAN, Cellular, Satellite, and GPS into a sophisticated network that meets your specialized needs. With our standard telemetry products and customized design services option, we can provide a system that fits your specific needs – all with components that are designed and manufactured to withstand severe temperature, vibration, and sealing requirements.

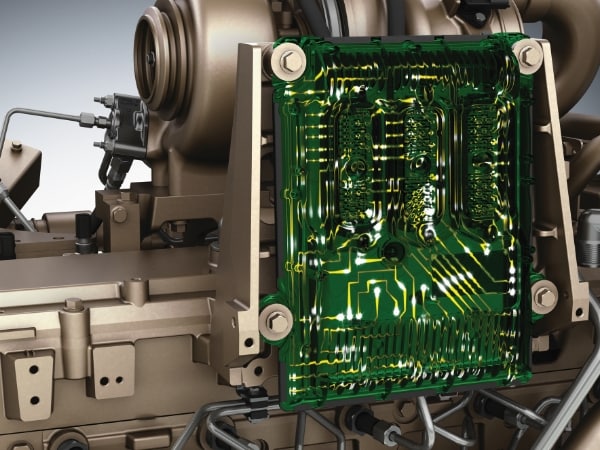

Electronic Controls

Built to Work – Built to Last

Our customers push the limits of our mechanical durability, with expectations of reliable operation in severe heat and extreme cold, harsh chemical vapors, and direct exposure to water, dirt, dust, and rock. Our hardware and software engineering teams use proven production/design libraries to build dependable products that monitor a wide array of common and custom I/O parameters, provide for load control and protection, as well as multiplex networking using distributed and discreet architectures, such as CAN , SAEJ1708 and SAEJ1939 standards.

Capabilities

We enhance our products mechanically by using our automated conformal coating equipment and full potting capabilities to ensure product survival in the worst conditions. Our unique, patented electronic packaging technology provides improved sealing and component density, so our control modules are waterproof, dust-proof and thermally protected. These units are able to survive the harshest environments while efficiently managing thermal loads from high-current electrical solid-state switching devices.

Power Electronics

Electronic Solutions on the Move

Here at John Deere Electronic Solutions, we are implementing leading-edge technology, testing equipment and production facilities to develop and manufacture rugged Power Electronics that provide reliable, efficient alternatives to mechanical or electro-hydraulic systems. We have the technical capabilities to design everything from inverters, converters, and power distribution

Expandable/scalable architectures

Systems for permanent magnet motors, switched reluctance motors, and induction motors. Replacement of mechanical and electro-hydraulic systems in agriculture, construction, trucking, consumer equipment, and industrial applications/ Drive system electrification for small and large equipment, vehicles and recreation products