Generator Drive Applications: Non-Regulated G-Drive Engines

Confidence is built in

You can count on John Deere PowerTech™ generator drive engines to start in the morning, operate efficiently all day, and work reliably for many years. But pure product performance isn’t the strongest thing about working with John Deere. It’s the confidence of having the John Deere integration and support network at your side every step of the way.

Prime or standby power

John Deere generator drive engines are ready when and where you need them. They provide fast response for standby situations and exceptional load recovery in a wide variety of applications.

The power of choice

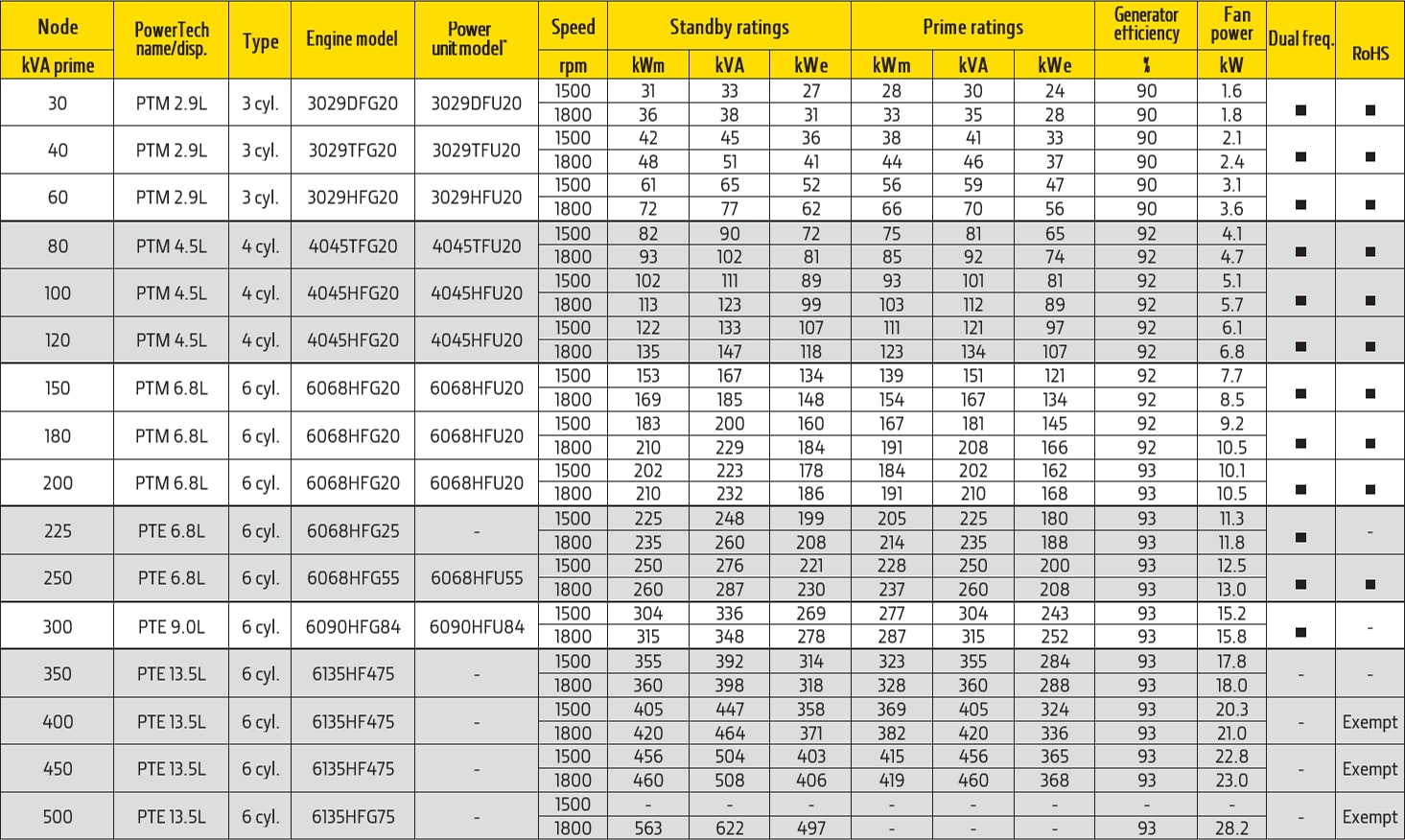

Why build your gen-set around someone else’s engine? With John Deere, you get a wide range of configurations and accessories so you can specify the right generator drive engine that best fits your application. Our preconfigured options can save you hours of engineering time and help you get machines to market faster.

Integration assistance

You get expert integration assistance provided by John Deere engineers and distributors. OEMs can put our application engineering experience and know-how to work to save development time and money.

Customer support

With more than 4,000 John Deere service locations worldwide, you never have far to go to find expert assistance and advice.

Fast parts delivery

Our distributors and dealers stock maintenance parts, as well as many other common replacement parts, to meet your service needs quickly. Our worldwide parts distribution system also provides overnight delivery in most regions.

Engines for non-emissions certified applications and regions not subject to emissions regulations*

* Power unit includes factory-mounted cooling package, air filter, and feet.