A smart, performance-driven approach to emissions compliance.

You can count on John Deere PowerTech™ industrial engines to start in the morning, operate efficiently all day, and work reliably for many years. But pure product performance isn’t the strongest thing about working with John Deere. It’s the confidence of having the John Deere integration and support network at your side every step of the way.

Off-highway experience

John Deere specializes in rugged off-highway applications. That’s why our engines are built with heavy-duty components, top-liner cooling, steel pistons to maximize reliability, and wet-type cylinder liners for long-haul durability.

The power of choice

With John Deere, you get a wide range of configurations and accessories so you can specify the right engine that best fits your application. Our preconfigured options can help save hours of engineering time and help you get machines to market faster.

Integration assistance

You get expert integration assistance provided by John Deere engineers and distributors. OEMs can put our application engineering experience and know-how to work to help save development time and money.

Customer support

With more than 4,000 John Deere service locations worldwide, you never have far to go to find expert assistance and advice.

Fast parts delivery

Our distributors and dealers stock maintenance parts, as well as many other common replacement parts, to meet your service needs quickly. Our worldwide parts distribution system offers overnight delivery in most regions.

Engines for EU Stage V applications

Stage V engine technology

PowerTech EWX

EWX engines are compact, powerful, cost-effective, and simple to install without requiring cooled EGR or SCR. Our straightforward PowerTech EWX 2.9L and 4.5L engines have 2-valve cylinder heads, high-pressure common-rail fuel systems, and full authority electronic controls. They use simple wastegate turbocharging to maintain transient response and peak torque in all operating conditions.

PowerTech PWS

PWS 4.5L and 13.6L engines combine advanced combustion technologies, enhanced engine calibration, and simple wastegate turbocharging. PWS engines feature PowerTech Plus technology with a DOC/DPF and an SCR system that reduce emissions while maximizing performance.

PowerTech PVS

PVS 6.8L engines deliver more power, torque, and fluid economy. They utilize our proven PowerTech Plus technology with variable geometry turbocharging, a DOC/DPF, and an SCR system to improve combustion efficiency, reduce emissions, enhance performance, and improve fluid economy.

PowerTech PSS

PSS engines provide a powerful combination of power density, performance, and fluid efficiency. For ultimate performance in off-highway applications, PowerTech PSS 4.5L, 6.8L, 9.0L, 13.5L, and 13.6L engines can handle almost any job. All displacements feature series turbochargers to deliver excellent performance and responsiveness. PSS engines feature proven PowerTech Plus technology that includes a DOC/DPF and an SCR system designed specifically for off-highway applications.

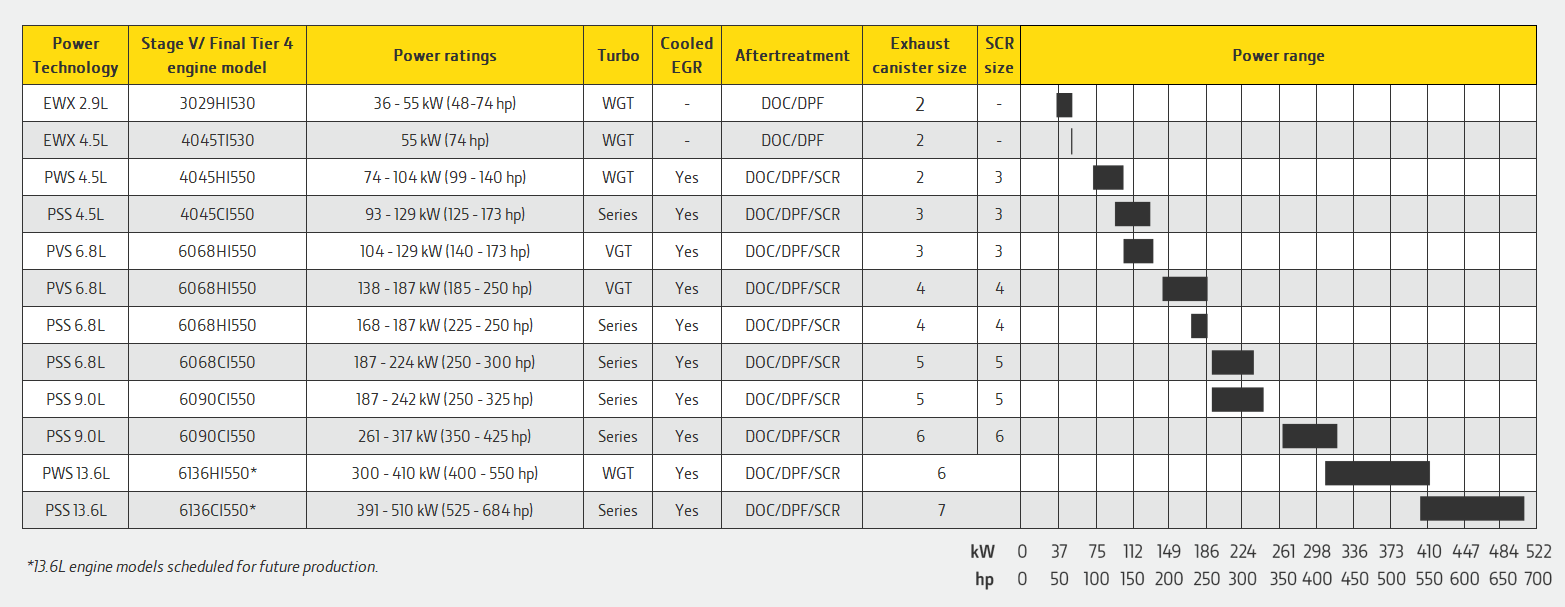

Industrial engine power ratings